Company:

Company:

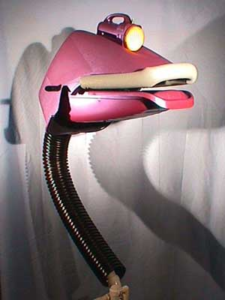

Mystery Science Theater 3000, an award-winning television comedy, created many unique puppet characters in the course of its 20-year existence. The show quickly became a cult classic and is still popular today with a large devoted fan base.

Challenge:

Producers wanted to create a collector’s item of one of the show’s robot characters. The “real” robot puppet was over 6 feet tall, so a life-sized replica was impractical and too expensive to make.

They decided to scale the robot down to a 6”-tall size. Since they had already recreated another scaled-down puppet character using this technology, they knew that 3D laser scanning would provide the most accurate and detailed model from which realistic figures could be easily manufactured.

Solution:

The puppet itself was located in Minnesota, so the manufacturer, Bamco, searched for a high-quality 3D scanning company in-state to perform the scan, and found Laser Design Global Services. Using Laser Design avoided long-distance shipping of the robot and sped the digitization process. The Laser Design account manager discussed the project with MST 3000’s contacts and quickly moved into the scanning phase. It was important that the process be non-destructive because there was only one “real” puppet of the popular character. Because laser scanning is non-contact, the figure’s geometry could be captured without touching or distorting the free-form shape.

The Laser Design account manager was very helpful, very communicative with us. He kept us updated on the scan project, how the base design piece was progressing, and in general he shepherded the changes along quickly. He also made sure the correct type of CAD files for our fabrication process were delivered. The results were great.”

Laser Design engineers scanned the large puppet character on the Laser Design SURVEYOR™ FA Series 10’ Platinum Faro-Arm 3D laser scanning system with the speedy Laser Design SLP-2000 laser line scanning probe, the longest-line (10”) scanner available on the market.

This means that the scan was done in a fraction of the time of shorter-line scanners; the accuracies of the long-line scanner (75µm) were high enough for this type of reverse engineering application. The set-up and scanning process comprised two-parts:

- Scanning the whole assembled part took 1½ hours to complete;

- Scanning the four individual disassembled parts took 4 hours to complete (1. top half of the puppet head, 2. bottom half of the head, 3. neck tube, and 4. rod that held the “mouth” in place)

Scanning both the assembly and individual parts assured that all surfaces were thoroughly captured in the scan data.

Because the non-contact laser scanning system projects a line of laser light onto all of the part’s surfaces while cameras continuously triangulate the changing distance and profile of the laser line as it sweeps along, the problems of missing data on complex free-form surfaces are greatly reduced.

The laser line moves back and forth over the part until the area is captured digitally. The system measures fine details so that the object can be exactly replicated in a CAD model. Laser scanners measure articles quickly, picking up to 75,000 coordinate points per second, and generate huge numbers of data points without the need for special templates or fixtures.

The puppets body had no internal cavity; therefore the scan was able to reproduce the entire part’s profile completely and precisely in the coordinate point cloud. The native software automatically connected the point cloud data from multiple views into a common coordinate system in a single scan file of the assembled puppet. After the scanning was complete, the raw data was processed and refined into a complete point cloud model.

The 3D point cloud data was taken directly into Geomagic Studio, modeled into a non-parametric (“dumb”) solid model, scaled down to the desired size. This format was chosen because it could be used by the manufacturer to make the molds as-is, without costly reworking, precisely preserving the geometry of the complex, free-form parts.

Using touch measurement technologies to capture the puppet’s curved irregular shapes could have taken 20 times longer, and would have resulted in a much less complete data set. Measurements taken by hand would have been sparser, never really capturing the totality of the complex shapes. Without non-contact laser scanning, this type of exact replication would be virtually impossible.

To complete the scaled-down figurine’s structure, Laser Design performed another value-added engineering service for this project: product design. Bamco wanted Laser Design to design a proportional base for the small figurine in CAD since the real puppet was just a head and a neck, no body, no base. Laser Design engineers extracted the dimensions of the neck tube rings from the scan data and created a coil of tube for the base on which the figurine stands.

The coil was designed only in CAD; no physical coil part existed. It was scaled to be proportional with the puppet head and neck and to function as a solid foundation, matching the size of and stabilizing the collectible figure. The professionals at Laser Design are experienced in these types of product design add-ons. The customer was extremely pleased with the results.

Results:

As expected, the laser scanning process worked very well in capturing the entire shape of the puppet and creating an accurate non-parametric model that was scaled down to the desired dimensions. This type of file format feeds directly into mold-making machines for easy fabrication.

“The Laser Design account manager was very helpful, very communicative with us,” said the MST 3000 manufacturing contact. “He kept us updated on the scan project, how the base design piece was progressing, and in general he shepherded the changes along quickly. He also made sure the correct type of CAD files for our fabrication process were delivered. The results were great.”

An extra value-added component Laser Design provided was a colored version of the model as a native ProE file. In this format the customer could see what the scan data looked like in a more “lifelike” color version and use it to illustrate their product concept to their manufacturer and other stake-holders.

The project was quoted for delivery in one week. Laser Design delivered in less time, even though the coil base design element was added to the scope. “We appreciated the timely delivery,” commented the manufacturer, “and the guarantee that the deliverables were exactly what we needed.”

The CAD model functioned perfectly at the manufacturer to fabricate the figurine molds. The scaled-down puppet figurine is now available on the MST 3000 website along with DVDs of the cult favorite’s shows. Laser Design’s expertise in collecting and preparing scan data for reverse engineering applications sped this project to a successful conclusion.