EasyTom Scanner by RX Solutions

Give our 3D Systems Specialists a call! 952-252-3471

Get a Complete Capture of Your Part with High Accuracy and Resolution Large Volume Inspection CT Scanners

Fast, Precise 3D measurements for large volume inspection

Significantly cut Time-to-Market with the DeskTom 3D Computed Tomography (CT) Scanner

EasyTom 130 & 150 Micro CT Scanners are x-ray inspection machines allowing a collection of complex internal and external geometry. The EasyTom 3D CT scanners features high-resolution digital radioscopy, versatility for a wide variety of applications, 6 motion axis and large volume inspection.

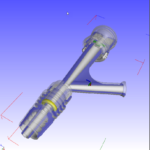

Parts with small, complex & fine geometry benefit especially from CT technology, since they are very difficult to measure using even the most advanced, laser-based scanning or CMM technologies.

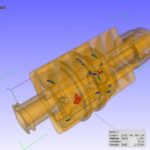

Metrology grade CT inspection allows a complete 3D capture of complex internal geometry of parts without needing visual access – the process is nondestructive.

CT scanning helps you capture all surfaces, both external and internal, of complex and free-form parts without damage to the object.

Real Time Scanning for Fast Measurements

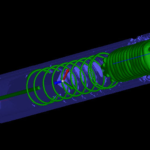

- Attain measurements in real time with high resolution digital radioscopy

Attains highly precise measurements

- Capture highly accurate measurements at 10µm Accuracy with Resolution to 4µm

- High accuracy motorized rotation and 3 Axis translations

Provides easy-to-use 3D scanning capabilities and a compact footprint

- Easy to use 3D micro and computed tomography system

Versatile for a variety of applications and parts

- Easily verify structure of 3D printed metal parts

- Full inspection of large size samples and high volume inspection.

For additional information and the latest case studies, videos and brochures regarding the EasyTom CT Scanner by RX Solutions, please visit the CyberOptics Product Page.

-

For full information on the EasyTom CT Scanner check out our brochure.

Check out our new White Paper: Industrial Radiography – CT Scanning for Metrology Applications (PDF)

View on CyberOptics Corporation Site