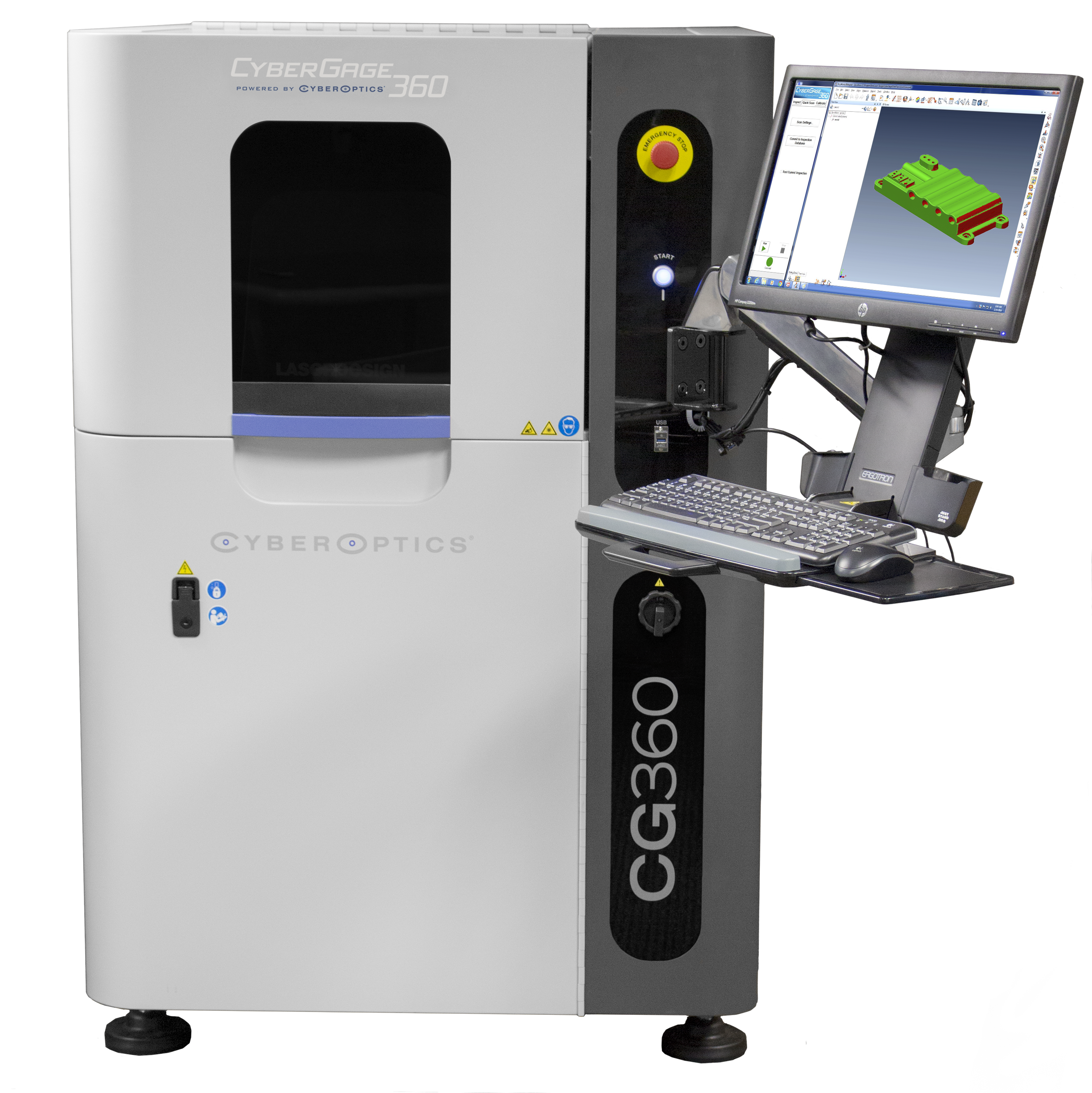

CyberGage®360

Give our CyberGage360 team a call! 952-252-3471

Unprecedented combination of speed, accuracy and one-button simplicity for non-contact automated 3D scanning inspection.

Dramatically Speeds Up Quality Assurance of In-Process Inspection and/or Incoming/Outgoing parts inspection; Lowers Cost of Quality & Speeds Up Product Time-to-Market.

Designed for use in general purpose metrology, the CyberGage®360 has a range of applications from medical to automotive to aerospace to consumer electronics, where high accuracy and high speed throughput are important.

High-Precision accuracy with Multiple Reflection Suppression (MRS) Sensor Technology

High-Precision accuracy with Multiple Reflection Suppression (MRS) Sensor Technology

- Generates an automated, highly precise, full 360⁰ volumetric scan with NIST traceable accuracy to 7 µm + L/10000.

- Incorporates CyberOptics’ proprietary 3D Multi-Reflection Suppression (MRS) technology that enables metrology-grade accuracy by inhibiting optical measurement distortion and reflections.

Easy-to-use Software with Push-Button Automation

- Simplifies scanning with one-button simplicity

- Provides factory-friendly operation with minimal training

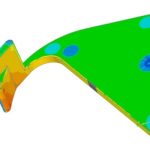

- Generates automated inspection reports including a comparison of scan data to CAD models or models based on ‘golden’ examples.

- Programs off-line with pre-defined inspection templates

- Speeds part program selection with Bar Code Part ID

- Eliminates inspection gages with fixtureless design

- Offers quick and simple field recalibration

Automated 3D Volumetric Part Scan and Inspection Report in less than 3 minutes

- Quickly generates a highly precise, full 360⁰ volumetric 3D surface scan of complex shaped parts in <3 minutes

- Facilitates near-production line high-volume scanning and high speed throughput

For additional information and the latest case studies, videos and brochures regarding the CyberGage360, please visit the CyberOptics Product Page.