The Company

Didrick Medical, Inc. is a small privately owned company that designs and fabricates active-function artificial finger prostheses, called the X-Finger®, for partial finger amputees. The owner refined the design for over 6 years before he took it to the marketplace. The device is body-powered, light-weight, and allows users to regain complete control of the flexion and extension movements of an artificial finger in a self-contained device. Each X-Finger® is custom fabricated to accommodate a variety of finger amputation cases. “Our current direction is to use emerging technologies to improve the lives of people who have lost fingers,” said the owner. The U.S. Department of Defense is funding the company’s research into a functional thumb. Didrick Medical holds patents for the X-Finger technology in over 140 countries.

The Challenge

Because most artificial fingers in the past were cosmetic, not articulated and not functional, Didrick Medical wanted to combine the most realistic look with the most realistic action. In addition to being functional, Didrick Medical wanted to insure that each finger prosthesis was custom fit to the amputee’s hand, something that is very hard to standardize. Both the number of fingers needed and the size of the hands can differ, making the number of assembly permutations practically infinite. He needed a faster and more accurate way to measure each individual hand so that he could provide the best design and fit possible, as well as timely service. Since the X-finger moves through the muscular movement in the remaining fingers, hand, or wrist, and not batteries, customization was essential to the functionality of the product. Articulation was necessary to give the hand full finger dexterity and function.

Because most artificial fingers in the past were cosmetic, not articulated and not functional, Didrick Medical wanted to combine the most realistic look with the most realistic action. In addition to being functional, Didrick Medical wanted to insure that each finger prosthesis was custom fit to the amputee’s hand, something that is very hard to standardize. Both the number of fingers needed and the size of the hands can differ, making the number of assembly permutations practically infinite. He needed a faster and more accurate way to measure each individual hand so that he could provide the best design and fit possible, as well as timely service. Since the X-finger moves through the muscular movement in the remaining fingers, hand, or wrist, and not batteries, customization was essential to the functionality of the product. Articulation was necessary to give the hand full finger dexterity and function.

Realizing that in order to create prosthetics for a wider marketplace he needed the digital CAD models that are used in manufacturing, Didrick Medical’s owner taught himself CAD and recreated his physical designs digitally in SolidWorks. This was excruciatingly time-consuming and because each customer needed a totally new set of specifications, the time involved and the pricing became prohibitive.

The owner explains, “A lot of research and development is being devoted to making functional artificial arms, but the technology stopped when people only lost fingers.” His design links portions of the hand and fingers together so that they work naturally as a unit. The problem was not making the finger look real, cosmetically identical fingers had been made for years, but functional and realistic fingers were new to the scene.

He began to search for a quicker and more accurate way to generate the hundreds of measurements he needed to create just one custom hand prosthetic. He found Laser Design Global Services, a division of Laser Design, Inc., through an Internet search and contacted Larry Carlberg, Laser Design Service Bureau Manager about the possibility of doing a test scan on two small woman’s hand casts that he was working on.

The Solution

Carlberg knew from his decades of experience that non-contact laser scanning would provide the ideal solution to Didrick Medical’s challenge of digitizing the complex natural shapes of an amputee’s hands. He commented, “Freeform shapes are ideal for laser scanning, since it is impossible to capture these organic shapes in any other manner.” Because the laser scanning system projects a line of laser light onto surfaces while cameras continuously triangulate the changing distance and profile of the laser line as it sweeps along, the problems of missing data on a freeform, irregularly shaped surface is eliminated. The system measures fine details and captures complex geometry so that the object can be exactly replicated. Laser scanners quickly measure articles, picking up tens of thousands of points per second, and generating huge numbers of 3D data coordinates without the need for templates or fixtures.

To scan the two hand casts, Carlberg used the Laser Design Surveyor 3500 3D laser scanning system with a Pentium 4, 3 GHz processor with 4 GB RAM and a specialized video card. The laser probe used was an RPS 450, since it has a deep depth of field with good accuracy. He performed multiple scans mounting the casts on the Aerotech rotary stage to capture 360 degrees of the casts’ geometry. The Laser Design 3500 machine setup is automated to merge multiple scans into a single point cloud using the rotary stage integrated with the native data collection software Surveyor Scan Control (SSC).

The casts each took approximately one hour to scan. Compared to manually measuring, the time savings are enormous. “The process of laser scanning cut 60% off the time it took to make enough accurate measurements of the hand casts to create a CAD model,” said Didrick Medical. “With over 600 different variations of each finger-hand configuration, such as how much of the finger is gone, which fingers are gone, and so on, plus six different hand sizes, getting the correct measurements is an incredibly labor-intensive task with manual measuring tools. The speed and accuracy of laser scanning allows me to standardize assemblies and sizes and make all the parts interchangeable. In the future, this will reduce the cost, increase availability and make the process easier and faster for the benefit of the amputee customers.”

“I can’t think of an alternative to 3D laser scanning that would provide similar results. The geometry is just too amorphous to capture without laser scanning,” Carlberg added. “The output we delivered for these parts is highly accurate since we create the solid models directly from scan data. The accuracy of the point data is .002” or .05 mm of the actual hand cast. To achieve a model of free form shapes with this kind of accuracy is impossible by any other means. With such an accurate definition of the actual hand, Didrick Medical can fit a prosthetic device perfectly.”

“I can’t think of an alternative to 3D laser scanning that would provide similar results. The geometry is just too amorphous to capture without laser scanning,” Carlberg added. “The output we delivered for these parts is highly accurate since we create the solid models directly from scan data. The accuracy of the point data is .002” or .05 mm of the actual hand cast. To achieve a model of free form shapes with this kind of accuracy is impossible by any other means. With such an accurate definition of the actual hand, Didrick Medical can fit a prosthetic device perfectly.”

Didrick Medical agrees. “In the past, hand prosthetics relied heavily on a fabricator’s artistic ability and creativity. They were visually realistic but not functional with articulation and mobility. Now technology is catching up and complexity is increasing so that not only does the prosthetic look realistic, but it acts realistically too. All our complex components are hinged in more than one place so organic hand movement is duplicated. The residual parts of the fingers stabilize the prosthesis and the grasping functionality is speed-regulated like a real hand’s. The technology is available today is unbelievable. It has given rise to a new profession, the anaplastologist, a career which has actually been around for over 20 years, but now has its own advanced tools rather than ‘making do’ with materials used in the special effects industry.

“Today, the realistic look and movement can all be created through measuring and duplicating technologies. It is quicker, cheaper, and provides better access to people all around the world. This is an exciting time for the prosthetics business. Every day we find out new ways that technology can aid us.”

The Results

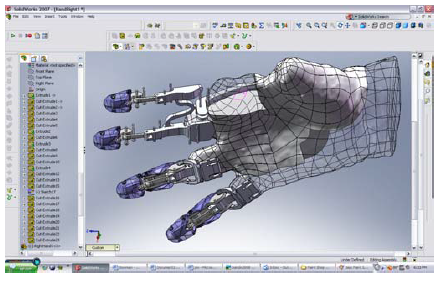

“The files were perfect,” said Didrick Medical. “They imported as solids into SolidWorks, and I was able to do cross-sections and use the side views, which is essential to creating custom prosthetic finger assemblies.” Laser Design’ expert metrologists made the 3D scanning process quick, accurate, and cost-effective from start to finish, allowing Didrick Medical to completely bypass time- consuming manual measuring. Laser scanning brings the custom fabrication process for prosthetic fingers several steps closer to being an off-the-shelf product.

“Didrick Medical has the most technologically advanced artificial hand/finger in the world. It fills a huge gap in the prosthetic industry for finger amputees.” Didrick Medical input the custom data into SolidWorks and fabricated components customized for that individual’s hands.

The extreme speed and accuracies of the point data (002” / .05 mm) are typical for Laser Design’s work in this type of application. “The success of this story describes a unique application of utilizing a very fast an accurate scanning system with an ideally suited software (Geomagic Studio) for developing quick models of amorphous shapes,” explained Carlberg.

Didrick Medical concluded, “What you gave me was exactly right. The Laser Design metrologists provided all I had hoped for in the scan data and more. I am totally happy with the results.”