A  3D scanner provides new inspection options and a faster alternative to CMM for this engineering and mold manufacturing company.

3D scanner provides new inspection options and a faster alternative to CMM for this engineering and mold manufacturing company.

As featured in MoldMaking Technology! See published article here.

by Bob Cramblitt

It doesn’t look like the headquarters of a mold-making innovator: the low-slung, elongated ranch house of a building on the outskirts of Rutledge, Georgia (population 780), about 50 miles southeast of Atlanta. But looks can deceive, especially when it comes to Versatile Mold and Design.

Inside that 35,000-square-foot facility is a company providing precision mold design and manufacturing for companies such as Schneider Electric, Eaton Electrical, GE, Siemens and Husqvarna. The company also has an office in Shenzhen, China, that supports offshore work.

Versatile Mold and Design has spent close to $2 million over the past two years in new technologies for cutting, electrical discharge machining (EDM), laser welding and grinding. One of its best investments, according to company president Bob Heusser, is a Surveyor Series 3D scanner from Laser Design Inc.

“Our largest customer, Schneider Electric, required that we buy the laser scanner to reduce project turnaround times, especially for part inspection,” says Heusser. “It’s also led to a major reduction in dimensional corrections of new tooling.”

From weeks to days

From weeks to days

The Laser Design Surveyor 3D scanner used by Versatile has an accuracy of +/- 0.010mm. Setting up a new part scan takes only a few minutes. Programming a part inspection process is automatic using PMI (part manufacturing information) data that designers can include in the CAD model.

“The automation removes the need for a 3D scanning specialist,” says Marty Schuster, Laser Design president. “The user can be just about anyone.”

Versatile Mold’s Laser Design Surveyor system includes embedded inspection software that compares 3D scan data to a CAD model and extracts all GD&T (geometric dimensioning and tolerance) data and critical dimensions automatically.

The improvement between CMM and 3D scanning inspection using the Laser Design Surveyor system has been dramatic, according to Trevor Martin, quality control technician for Versatile Mold and Design.

“Our inspection process before was slow. You had to pick the points manually, and put all of the data into an Excel spreadsheet, which can take weeks depending on how many dimensions there are in your part.

“The Laser Design Surveyor enables us to scan the part automatically and capture hundreds of thousands of points instead of a few dozen. You can select points and it automatically gives the dimensions. With one click of a button all of our data is exported to an Excel spreadsheet. With a CMM if you have a four-cavity tool you have to check each part (cavity) individually. With the 3D scanner, you check one cavity and run the automation on the other three cavities and your inspection is done.”

The ability to capture millions of points, faster and more accurately, and automatically integrate them into a spreadsheet turns formerly weeks of inspection into days, according to Martin.

>Getting it right the first time

Versatile has gone beyond first-article inspection to incorporate the Laser Design Surveyor into faster, more accurate production of electrodes that are machined to burn steel during mold production. A complex mold can use dozens of small electrodes with intricate shapes and myriad depths. Before bringing the scanner into the process, there was no way to check every aspect of an electrode before manufacturing.

Now, Versatile produces carbon electrodes and checks each one before the steel-burning process to eliminate mistakes.

“This is an incredible pre-check, as carbon is much cheaper than steel,” says Rus Emerick, director of application engineering for Laser Design. “Versatile realizes the value in burning steel right the first time rather than finding out an insert or mold is incorrect only after parts have been molded.”

An elegant solution

An elegant solution

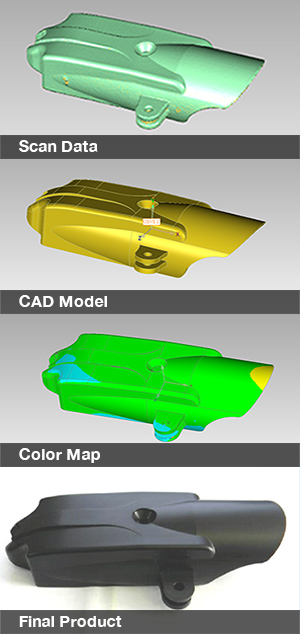

A recent project for Utility Inc., a provider of real-time data acquisition systems for mobile operations such as transit systems and law-enforcement, demonstrates how Versatile uses 3D scanning to accelerate product development and ensure part quality.

Versatile provided all the plastic parts for Utility’s Rocket vehicle router, a system used by Atlanta PD and other police departments to provide a continuous video feed from squad cars to headquarters. One major challenge was creating a mold for the video camera cover.

“The design needed to be integrated with the existing mold of the camera and not appear as an afterthought or a kludgy quick fix,” says Ted Davis, president and chief technology officer for Utility. “The elegant design was a joint effort between Utility and Versatile Mold. From design to first article it took about eight weeks. The outcome couldn’t have been better.”

Versatile scanned the Utility camera, then reverse-engineered the scan to produce a CAD model of the camera. Based on that CAD model, Versatile’s engineers designed a perfectly fitted cover and mount for the camera.

“We needed to match the housing geometry of the cover to the camera,” says Martin, “and highly accurate 3D scanning was the only way to do that.”

Electrodes were machined to burn the steel and produce the mold. The electrodes were scanned before burning to confirm their accuracy compared to the CAD model. Sample parts produced by the mold were then laser scanned and compared to the 3D part model for accuracy.

“3D scanning using the Laser Design Surveyor system saved significant time and validated not only the fit, but confirmed the overall look of the final product,” says Davis. “Only one SLA (3D print) prototype was required thanks to 3D scanning validation. This allowed for an accelerated project and reduced the total cost as well.”

ROI and new business generator

ROI and new business generator

The accuracy, speed and ease of use of the Laser Design Surveyor has proven to deliver not only major benefits for Versatile’s design and manufacturing processes, but to the company’s bottom line as well. Versatile believes it recouped the initial cost of the 3D scanner — approximately $150,000 for the machine and the inspection software — in about a year by speeding project turnaround time and eliminating mold errors.

The Laser Design Surveyor 3D scanner and the other investments made over the last two years have helped Versatile gain approval for mold-making by major companies in the medical device industry, including Covidian, Medtronics, Vention Medical, Med Tech of Georgia and Nypro Healthcare.

“Versatile has become a more efficient organization both from design and production standpoints over the years, expanding its facilities and investing in technology in order to keep pace with demands,” says Davis of Utility Inc. “We are very demanding of our suppliers and Versatile Mold and Design stands out as a trusted partner that has helped make our rapid growth possible.”

###

Bob Cramblitt writes about design and engineering technologies that transform the way we live, work and create.