Donnelly decided to expand its QA function with the innovative technology of 3D scanning in direct response to customer demands for speedy precise inspection services for their increasingly more complex free-form and curvilinear part surface profiles.

Donnelly decided to expand its QA function with the innovative technology of 3D scanning in direct response to customer demands for speedy precise inspection services for their increasingly more complex free-form and curvilinear part surface profiles.

The Company:

Donnelly Custom Manufacturing Company, based in Alexandria, MN, is a leader in short-run injection molding. With over 200 employees, Donnelly sets the standard of excellence in custom injection molding by delivering exceptional service and solutions to help their leading industrial OEM customers succeed.

Donnelly’s guiding principles include speed and service, along with an underlying commitment to quality and on-time deliveries. Since the company hosts its own inspection department, staying up-to-date and using the latest technologies and best practices is an integral part of the company approach. They had used a CMM to fabricate parts, but more and more customers were asking for detailed solid models in some dimensions, something they were not equipped to deliver.

The manufacturing launch engineer, who links the engineering phase to the part manufacturing phase through the critical launch process, had read about laser scanning in trade articles and wondered if it could improve Donnelly’s quality inspection process. He had researched the technology on the Internet and was impressed with its potential to quickly provide precise geometric dimensions without contact to the part. But the deciding factor in finally purchasing a 3D laser scanning system was when he saw a special offer from Laser Design on a complete system. The price was right and Donnelly leveraged the savings opportunity and purchased the system.

The Rationale:

The speed and accuracy of laser scanning fits perfectly with Donnelly’s underlying principles of speed, service, and quality because non-contact laser scanning radically speeds up data gathering and analysis while maintaining exceptional accuracies. Many industries are now benefitting from the increased speed of 3D laser scanning along with traditional metrology methods to significantly reduce the time required for first article inspection of their products. Inspection is one of the main applications of non-contact laser scanning technologies and includes first-article inspection, last-article inspection, in-line inspection, in-process inspection, and many more.

Today more than ever, speed and quality give product manufacturers the competitive advantage; reducing time to market creates the biggest opportunity to increase bottom-line profitability. Donnelly decided to expand its QA function with the innovative technology of laser scanning in direct response to customer demands for speedy precise inspection services for their increasingly more complex free-form and curvilinear part surface profiles.

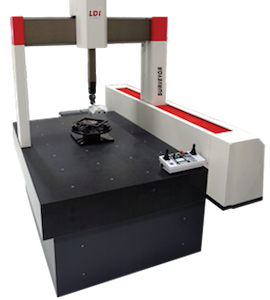

The company purchased a Laser Design 3D laser scanning system with dual lasers. Engineers attended week-long training on the system and Geomagic Qualify software as their first step in becoming proficient in the first-article inspection process. Laser Design also provided some scanning expertise through its service bureau to help Donnelly with its first couple of projects.

The Challenge:

Donnelly creates short-run injection mold tooling for over 200 new parts each year. To do this, engineers wanted to be able to scan production parts with single or multiple cavities to yield an accurate depiction of the surface geometries. From this precise data set, they can create the complex tooling to make the parts. Since some production problems stem from tool design deficiencies, the manufacturing launch engineering review is essential in making sure the tool is constructed properly and the launch goes smoothly.

Laser scanning at this phase provides the engineers with comprehensive 3D data of the part’s profile so they can more completely assess the moldability of the part. The system reduces time spent in producing parts and enables Donnelly employees to focus on their areas of expertise–the actual design and molding issues–much more quickly. Donnelly engineering and manufacturing launch personnel strive to sample and inspect parts within two weeks of delivery.

One early project involved Donnelly’s customer wanting a molded credit card printing machine. The machine had approximately 30 parts; scanning was performed on the two of them which were causing problems for reverse engineering. Once the parts were fabricated, they were scanned as-is to determine where they were deficient by comparing the actual scan data to the dimensional drawings and layouts. The Donnelly engineers expected to use laser scanning for inspection applications, but the usefulness of the system in reverse engineering parts as-is for this QA process, produced an additional benefit. With the newly acquired scan data to compare to the old CAD data, they could refine the precision of the molds to a higher degree.

The Solution:

The Solution:

With assistance from the expert engineers at Laser Design, the credit card printing machine parts were quickly scanned on the Laser Design SURVEYOR DS-system. Because the laser scanning system projects a line of laser light onto all of the part’s surfaces while cameras continuously triangulate the changing distance and profile of the laser line as it sweeps along, the problems of missing data on curvilinear or irregular surfaces are greatly reduced.

The laser line moves back and forth over the part’s surface until the complete area is captured digitally. The system measures details and complex free-form geometry so that the object can be exactly replicated digitally and compared to other reference drawings to generate a color-coded error map for inspection. Laser scanners measure articles quickly, picking up to 75,000 coordinate points per second, and generate huge numbers of data points without the need for special templates or fixtures.

Scan time for the two machine parts was approximately 1 hour. Using touch measurement technologies to capture the parts’ curved irregular shapes could have taken 20 times longer, and would have resulted in a much less complete data set. Measurements taken by hand would have been very sparse, never really capturing the totality of the shape. And without the scan data, there is no compelling way to verify whether the parts are indeed correct, or by how much they are off.

After the 3D laser system scanned the parts, the native SSC software automatically connected the point cloud data from multiple views into a common coordinate system in a single scan file. An STL file was created which revealed the irregularities in the surface.

The Results:

The resulting color error map showed that the surface of the mold was off by a few thousandths of an inch when overlaid on the CAD dimensional drawings of the parts. This knowledge allowed the engineers to refine the electrode used to burn the mold and to add material across one surface to bring it into specification. The process was much faster than the traditional measuring technologies Donnelly previously employed and provided an easy-to-visualize color portrayal of the dimensional discrepancies over the entire part, not just a few sections or features. This meant that the execution of the scan was good, the reports were good, but the mold and the part needed some work.

As Donnelly personnel become more proficient in using the Laser Design scanning system and the Geomagic software, the results will be available faster to the manufacturing function and create a more seamless transition with the quality inspection process.

“We are excited to use this new laser scanning technology on projects,” commented the manufacturing launch engineer. “Geomagic Qualify is a monster program. Fortunately, their support system is very helpful and their response times are good. We have held a few go-to meetings with their software specialists to answer our questions and help us to develop our data processing abilities with it.”

Donnelly intends to outsource the few occasions when they must reverse engineer a part in the future since the data processing skill set is quite different from the inspection data processing skill set. Donnelly’s commitment to maintaining speed, service, and quality on their customer’s projects necessitates that they have a large arsenal of tools including manual CMM, DCC CMM, vision systems, and manual calipers at the ready. The Laser Design SURVEYOR 3D laser scanning system is a strategically important tool Donnelly can now incorporate to meet the demand for high-quality data with a speedy turnaround for the complex curvilinear parts they create.