A custom hand-crafted a molded intake tube was built for a Corvette to increase the high speed performance. To fabricate the tube a digital model was needed and 3D scanning was the only solution able to handle the challenge.

A custom hand-crafted a molded intake tube was built for a Corvette to increase the high speed performance. To fabricate the tube a digital model was needed and 3D scanning was the only solution able to handle the challenge.

The Company:

Recognized as a pioneer and leader in the rotational molding industry domestically and internationally, the company is known for innovative design and the ability to incorporate new technology and new materials in state-of-the-art products for a wide variety of businesses. Rotational molding is the company’s new plastic process that combines economy, versatility, strength and lightness in a wide range of products.

The Challenge:

The company’s client had custom hand-crafted a molded intake tube for a Corvette to increase the performance of the car at high speeds. To fabricate the tube, the company would need to obtain exact dimensions of the model in order to modify, test, and manufacture it in their rotomolded plastic. Usually Corvette engines are built with components that balance high performance and efficiency for everyday driving. This aftermarket intake tube part upped the horsepower for enhanced (racing) performance.

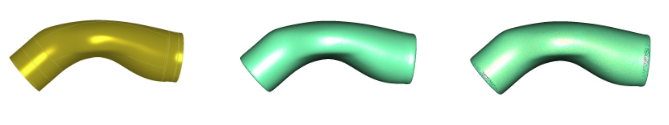

As always happens with a one-of-a-kind prototype, a digital model is needed so that it can be faithfully replicated in the prototyping and fabrication processes, for performance testing, and to maintain the high-performance features in the original design. Due to the complex curvature of the tube, the part would have been virtually impossible to measure and document with manual techniques. 3D scanning was the only solution that could handle the shape, the required accuracies, the modeling, and the budget involved.

The manager at the rotomolding company had seen e-newsletters about laser scanning from Laser Design in the past, but had not needed digitizing services at the time. When this project came up, he realized that 3D scanning would be the perfect solution and contacted Laser Design. He spoke with an account manager who explained that Laser Design engineers are experts at quickly capturing the geometry of complex free-form parts via a well honed laser scanning and CAD modeling process. The CAD data is provided in whatever format the customer needs. The company manager gave the go-ahead for Laser Design to proceed with the high-speed, high-accuracy digitization of the hand-crafted Corvette engine part.

The Procedure:

Laser Design engineers employed the SURVEYOR™ scanning system using the high-accuracy Laser Design SLP-400 laser-line scanning probe (with accuracies of up to 50µm) to precisely scan the intake tube’s complex curvature. This arm-based laser scanning system projects a line of laser light onto all the part’s surfaces while cameras continuously triangulate the changing profile as it sweeps along. The system captures the free-form surfaces completely, measuring details and complex curved geometry so that the object can be exactly replicated digitally. Laser scanners measure articles quickly, picking up to 48,000 coordinate points per second, and generate huge numbers of data points without the need for special templates or fixtures.

The Surveyor system’s native software, Surveyor Scan Control (SSC), took only a few minutes to set up and the desired scan data density was predetermined by the operator. The SSC software has a filtering feature that eliminates redundant points during the scanning process. The resulting point cloud is a totally comprehensive representation of the part.

Scan time for the Corvette intake tube was approximately 35 minutes. Without non-contact laser scanning, capturing enough data coordinates to accurately define the tube’s curved irregular shape could have taken 20 times longer, and would have resulted in a much less complete data set. Measurements taken by hand or on a CMM would have been much sparser, never really capturing the complete shape. Without the scan data, there is no way to verify whether the model is indeed correct, or by how much is it off.

After the 3D laser system scanned the entire intake tube, the native SSC software automatically connected the point cloud data from multiple views into a common coordinate system in a single scan file. The data was cleaned and aligned in less than 20 minutes. The scan data revealed that the hand-crafted plastic intake tube was not completely symmetrical, so the subsequent digital modeling process made corrections to the scan data, bringing the solid CAD model back to the design intent—smooth, symmetrical, and with perfectly circular holes on both ends.

The Results:

The organic shape of the intake tube was modeled in Rapidform® in about 45 minutes. Rapidform excels at modeling free-form curves and geometry and also allows direct conversion into a Solidworks model. The final deliverable was a parametric SolidWorks CAD model.

Laser scanning is ideal for reverse engineering complex parts to create CAD models because the whole surface of an object is scanned, not just a limited sample of discrete points like in contact measurement. Parts can be modeled “as is” for exact replication or, as was the case with the intake tube, the original design intent of the prismatic shapes can be extracted even if the as-built part is warped, misaligned, or broken, typical for hand-crafted products. When taken into a parametric modeling CAD package, the “history” of the model is available to designers, so any version may be referred back to at any time in the re-modeling process. Design changes or variations can then be easily made.

With the parametric CAD model of the scan data, the company was able to create a few alterations to the part by changing the neck diameters and adding a mass air flow sensor mounting feature. This edited digital version was sent out for rapid prototyping. The resulting prototype was sanded and polished to create a smooth finished version. The finished prototype was used to make a mold from which multiple carbon fiber samples were made. These samples were used for preliminary performance testing.

Depending on the test results, the intake tube can once again be tweaked in CAD or if the desired capabilities are confirmed, the company will be able to quickly mass produce the tube for their client who provides these types of aftermarket parts for Corvette owners who want to increase the horsepower and high-speed level of driving. The company was very satisfied with both the customer service from the account manager and the scanning results from Laser Design engineers. “Laser Design was responsive to our needs and provided us with excellent, useful data files,” commented the company’s manager.