In this interview, Martin Schuster of Laser Design, Inc. talks with Will Soutter about how replacing traditional QA systems with 3D scanning can streamline processes and reduce time-to-market.

In this interview, Martin Schuster of Laser Design, Inc. talks with Will Soutter about how replacing traditional QA systems with 3D scanning can streamline processes and reduce time-to-market.

Q: Can you give us a brief introduction to the systems and services that Laser Design provides?

A: Laser Design, a fully owned subsidiary of CyberOptics (CYBE), is the premiere provider of ultra-precise 3D scanning systems and 3D measurement services.

Laser Design has helped customers successfully complete their most complex inspection, analysis, and reverse engineering projects for more than 30 years. Experienced metrologists and engineers know that today more than ever, accuracy, speed, and automation give manufacturers the competitive advantage.

Laser Design’s primary value proposition includes the substantial reduction of product lead times in the time-to-market product development cycle, labor savings, and consistency of QA process improvement.

Based on the automation of the 3D scanning inspection system technology, customers can realize significant inspection time reduction, with greater accuracy and complete 3D part comparison to CAD along with critical feature dimensions that are automatically reported.

Q: What are the challenges of implementing 3D scanning in traditional QA environments?

A: Every day of lost profits due to bottlenecks found in the often slow QA process for new products – getting through final tooling acceptance / first article inspection approvals – can be extremely costly. Most don’t know the cost per day for lost profits until they look closely.

Laser Design has often been addressed during the sales cycle with the question; “I really love your 3D scanning technology, but how can I prove the return on investment (ROI) and pay back of this system to my management?”

As an example, a Director of Quality Assurance at a company that makes plastic injection molded parts and the molds / tools that make those parts, has been asked by management to find a way to get production parts from the customer submitted CAD model into, and through the entire tooling development and piece part production process faster, with high quality, and with less labor costs.

But before spending the company’s hard-earned money, two important things need to be proven: that the 3D Scanning technology works faster, better, easier, more reliably, and with less labor, and that it will pay for itself quickly.

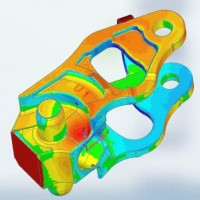

Getting the demonstrations for the 3D scanning inspection technology working on your parts is simple and straight forward. The 3D scanning technology is used to measure your parts to emulate what you are doing, along with additional analysis that your current methods can’t do – like complete part 3D color error maps to your needed tolerances.

The technology does it in X amount of time, with Y amount of programming, and Z amount of labor. If it meets or exceeds your needs and expectations, then the next step is to develop the business case and ROI analysis. This can be a daunting task, but a requirement for almost all investment decisions that organizations make for capital equipment expenditure budgets.

The real problem for this is: who has time in a busy day for an in depth investigation to ferret out all the benefits and costs for implementing a new QA process that may be resisted by a quality department that really doesn’t want to change?

So Laser Design teamed up with Edwin Boon, CEO of Rendement Group, a regional Black Belt QA consultant expert in both process re-engineering and financial analysis.

The objective was to develop an ROI analysis template comparing the use of the 3D scanning inspection systems vs. the customer’s existing QA processes.

The focus of the ROI analysis was the hard-dollar benefits derived from a shorter inspection cycle times, since this is always the strongest form of ROI to demonstrate.

Q: What aspects of the process typically yield the biggest time savings when switching to 3D scanning technology?

A: In the current state section of the ROI model, it clearly shows that due to the combination of samples, cavities, and dimensions, the inspection time in the Quality department is very labor intensive.

In fact, this is where the bottle-neck occurs in the product development life cycle, causing backlogs and delays in time-to-market. Where it may take hours to inspect a part with traditional machines, it takes minutes with 3D scanning technology.

Q: What was the resulting ROI in this case?

A: The sample part used in the ROI model showed the equivalent of 30+ man days saved, due to significantly less manual inspection time.

The result of the analysis showed that almost half the time of first article and part inspectors can be saved by replacing traditional equipment with 3D scanning systems.

We applied a weighted average based on revenue distribution to come up with an overall ROI for their company as a whole. The estimated time savings equated to about 40-50% reduction in time- to-market, which aligns with similar studies we’ve conducted at other companies.

Besides the time savings, the new technology would also detect and quantify defects not defined or inspected using 2D or more single location measuring technologies (CMM’s, Touch Probe measuring, Hand Held measuring tools, etc.).

Given the cost to implement a 3D scanning inspection process, the payback period was determined to be about a 9 months for the 3D scanning technology (Laser Design’s SURVEYOR ZS Series – CMM / Laser Scanning technology – accurate to +/- 6µ).

The cost of the SURVEYOR ZS Series – 3D Laser Scanning System was about $185,000 for a turnkey system solution.

Q: Tell us about the new CyberGage360 3D Scanning System – what makes this system so unique?

A: The highly accurate CyberGage360 combines the speed of 3D non-contact projection scanning with the ease of use and automation associated with the use of a common microwave oven.

One button controls the scanning and output of a complete inspection report. Anyone can use it with little training, which allows this technology to be located anywhere – office, factory floor, warehouse for incoming parts acceptance testing, or R&D for quick check of prototypes or 3D printed parts.

No other 3D metrology systems, or even 2D measuring systems, are at this level of ease of use. Plus, the system incorporates CyberOptics’ proprietary Multi-Reflection Suppression (MRS) technology for highly accurate scan data.

Q: Where can readers find more information about your 3D scanning systems?

A: Get in touch – our team will be happy to discuss our systems and how to prove ROI for your application.

Original interview can be found here.