Dentistry’s roots date back to prehistoric times when the practice consisted mainly of tooth drilling and extractions. The science of modern dentistry can be traced back to the 17th century when prosthetics and fillings were added to the original list of treatments. Since its humble beginnings, the field of dentistry has advanced and grown to include preventative, surgical, restorative, and cosmetic areas as well. Today dentists, orthodontists, and oral surgeons need advanced technologies to support their advanced care of the teeth, gums, and supporting bone structures.

Dentistry’s roots date back to prehistoric times when the practice consisted mainly of tooth drilling and extractions. The science of modern dentistry can be traced back to the 17th century when prosthetics and fillings were added to the original list of treatments. Since its humble beginnings, the field of dentistry has advanced and grown to include preventative, surgical, restorative, and cosmetic areas as well. Today dentists, orthodontists, and oral surgeons need advanced technologies to support their advanced care of the teeth, gums, and supporting bone structures.

For the last 25 years, Laser Design Inspection Services has been a leading provider of dimensional inspection,3D laser scanning, and CT scanning services for dentists who offer their patients innovative treatment options. The company’s metrologists and engineers are experienced in many manufacturing industries and have often been sought out to scan teeth, bones, and plaster casts of teeth and mouths as a means to provide dentists with faster and better oral health solutions.

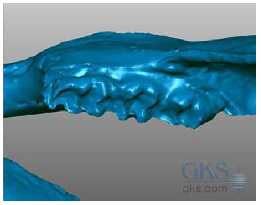

The recurring theme, and the biggest challenge, in scanning dental-related items is their organic nature; teeth, bones, and soft tissue shapes are very complex, free-form, and amorphous — and extremely difficult to replicate with traditional measurement methods. Gone are the days when patients are content with a dentist making a few rudimentary measurements with a caliper and creating an ill-fitting appliance or inaccurately restoring the surface of a tooth. Good looks AND a superb custom fit of any oral device are required for both cosmetic and health reasons in today’s marketplace.

Fortunately, non-contact 3D laser scanning’s forte is very accurately recreating difficult organic shapes, such as those found in the field of dentistry, which puts a smile on everyone’s face.

The manufacture of any 21st century part requires a CAD model—a digitized replica of the item— because manufacturing processes are highly automated and computerized. Computers tell production lines what to do and how to do it. As with most parts, dental molds, devices, and models are made and inspected from digital data.

What Dental Professionals Do

Dentists and oral healthcare professionals need to digitally replicate their patients’ mouths for many reasons. Depending on what work is to be done, the first step is to make an impression of a person’s teeth and jaw set. From that, a physical plaster model, or impression is created.

Once the physical model is made, Laser Design laser scans it thoroughly to bring it into the digital world. The process is automated and a whole mouth scan takes only a few minutes. The scan data is extremely accurate and can be used in many dental applications:

- General Dentistry: to build crowns and restore teeth and bridges.

- Oral Surgery: to fit partial and complete dentures, make devices to be implanted or fitted to the teeth and jaw, to reconstruct jaw bones from CT data for surgical restoration products..

- Orthodontics: to develop, build, fit, and improve appliances.

- Oral Healthcare: to develop and improve oral healthcare products

- Record Storage: to document and archive patient impressions, reducing storage space.

- Cosmetic Dentistry: to create and fit caps, “grills,” and other cosmetic items for teeth.

- Research: to model a specific condition or population for research.

- Reverse Engineering a Part: to reverse engineer (or recreate) an old part or device for which no CAD data is available

AREAS OF APPLICATION

General Dentistry

Dental patients nowadays are demanding that dentists restore the natural look and fit of decayed or missing teeth perfectly. The process starts when the dentist makes an impression of the patient’s mouth with a pliable silicon material. The patient bites down on the flexible block to lift impressions of both the top and bottom teeth and the oral cavity. From that impression, a model is cast with plaster which faithfully reproduces the mouth’s unique geometry.

Dental patients nowadays are demanding that dentists restore the natural look and fit of decayed or missing teeth perfectly. The process starts when the dentist makes an impression of the patient’s mouth with a pliable silicon material. The patient bites down on the flexible block to lift impressions of both the top and bottom teeth and the oral cavity. From that impression, a model is cast with plaster which faithfully reproduces the mouth’s unique geometry.

If an extraction or a crown is planned, then a replica of the original tooth is preserved in plaster. At this point, the plaster casts can be laser scanned quickly and accurately to produce digital data, and ultimately a CAD model from which to re-create the tooth or teeth that will be drilled or removed.

Crowns and bridges can be made to reproduce the real teeth so that the fit is just right. The clasps which hold these types of prosthetics in place must also be fit correctly to the remaining teeth to be secure and stable. Ill-fitting bridges or misshapen crowns can lead to irritation, compromising the patient’s oral health. Using 3D laser scanning to accurately restore teeth is good medicine as well as cosmetically appealing.

In addition, should more work be required in the future, the dentist already has all the patient’s 3D information available on file and can update it at any time.

Oral Surgery

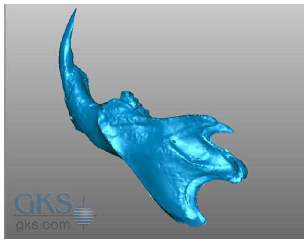

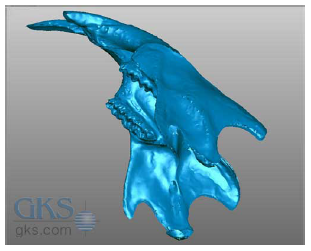

When surgery is required to extract several decayed or broken teeth, impressions are made beforehand so partial and complete sets of dentures that match the original teeth can be made. The modeling process is the same as for general dentistry applications, only more of the teeth and mouth shape will be recreated for partial or full dentures.

When surgery is required to extract several decayed or broken teeth, impressions are made beforehand so partial and complete sets of dentures that match the original teeth can be made. The modeling process is the same as for general dentistry applications, only more of the teeth and mouth shape will be recreated for partial or full dentures.

For patients with few or no teeth, an impression must precisely recreate the entire oral cavity, especially the toothless gums. Fit to the top or bottom arches and gums is critical to the success of any denture’s function. Slippage must be minimal to prevent sore gums and ensure an effective bite. To this end, the impression or the interior surface of the denture base must be extremely accurate so the dentures will securely seal against it. Laser scanning the impressions creates an amazingly detailed model; thus, an amazingly accurate fit is produced. Since dentures stay in place with the help of old-fashioned surface tension and friction, tight contact with the mucosal surface is essential.

Another application for the digital models resulting from 3D laser scanning is creating devices that will be fit to the teeth or jaw, or surgically implanted in the jaw. From digital data of the entire model, minute measurements and adjustments are taken to ensure the correct size and shape of the prosthetic part. The digitized data can be customized to whatever file format is needed to manufacture directly from the files.

Orthodontics

From the laser scans of an orthodontic patient’s teeth, digital models can be manipulated to simulate the individual’s progress from ongoing corrective treatments, and to manufacture devices to correct tooth alignment at every stage. The patient only needs to have one set of impressions made, an attractive option since the process can be time-consuming and somewhat uncomfortable. The subsequent device fitting is done through progressive CAD models of the patient’s teeth that digitally show the various stages of corrections.

Of course having numerous digital models of patients’ teeth and bites also lends itself to comparing and contrasting what makes them similar and different. This in turn may lead an enterprising orthodontist or dentist to make innovative improvements or add new features to the various devices used and make the orthodontic process better for many more patients.

Oral Healthcare

In order to design and manufacture oral healthcare items such as toothbrushes, electric toothbrushes, flossing devices, etc., a designer must have accurate measurements of a great number of teeth and mouths’ size, shape, and “layout” to assure a good fit and comfortable use in the general population. When a company spends millions of dollars to develop a new product, it must know that it will fulfill a need in the mass market and perform well. Laser scanning is a time-efficient and money-saving method to obtain measurement data on the geometry of thousands of oral cavities.

Archiving Impressions

Plaster impressions are very accurate representations of patients’ mouths which last for as long as needed. However, storing hundreds of sets of teeth can tax any office’s space constraints. Also, plaster impressions are breakable, so they must be carefully archived and stored separately.

Laser scanning impressions into digital data virtually eliminates the need for physical storage space. Once a plaster impression is digitized, there is no need to store the physical item and the data cannot be broken or damaged. Documentation is complete, and if an impression’s data is no longer needed, the record can simply be deleted off the digital storage medium rather than throwing away paper records which only puts more waste in landfills.

Cosmetic Dentistry

The same reasons that make laser scanning is so well suited to reconstructive dentistry, also make it an apt application for cosmetic dentistry. Grinding the teeth, age, a misaligned bite, fillings, and tooth decay all contribute to wearing down, cracking, and breaking of teeth. Dental caps cover the entire visible surface of an affected tooth and add strength, durability, and stability. The plaster impressions of the oral cavity are scanned and perfect-fitting caps can be matched to original teeth. Precise 3D digital measurements mean that they are made to exactly the right size, shape, and thickness to attach over existing teeth.

Another current cosmetic application, although much rarer, is using the laser scan data to make decorative “grills” or other “jewelry” items for teeth. Again, whatever the look, the items can be fit exactly over existing structures and the attaching hardware is sized to fit the places where they will be held on securely and prevent damage as well.

Dental Research

Plentiful scan data records mean that they can be compiled and analyzed for research purposes. If a condition or disease is prevalent within a population, cures or preventative measures may be found by modeling the characteristics or abnormalities found in the oral cavities. Data mining may also uncover unexpected or hidden trends and similarities within the groups studied. Laser Design has performed many scans on fossil teeth or mandibles to create research databases for anthropologists and archaeologists as well.

Plentiful scan data records mean that they can be compiled and analyzed for research purposes. If a condition or disease is prevalent within a population, cures or preventative measures may be found by modeling the characteristics or abnormalities found in the oral cavities. Data mining may also uncover unexpected or hidden trends and similarities within the groups studied. Laser Design has performed many scans on fossil teeth or mandibles to create research databases for anthropologists and archaeologists as well.

Reverse Engineering a Part with no CAD Data

As with any type of physical part that is manufactured, sometimes no CAD data exists for it. The part may be so old that it was originally manufactured in the days before digital models, or the CAD data may have been lost in time or when a company was sold and products specifications changed hands. In any case, today’s manufacturing processes, including those that make dental products, require a CAD model for tooling, molds, inspections of parts, and product designs or enhancements.

Laser scanning is the fastest, most accurate, and automated way to acquire 3D digital data and a CAD model of a part’s geometry when none is available. Re-creating complex free-form shapes is non- contact measurement’s best application. Both the positive and the negative version of a scanned part are easy to create, so no matter what part of a manufacturing process is lacking, 3D laser scanning can provide the correct type of data file. Also, new features and updates can be integrated into old parts once the modeling is accomplished.

Laser Scanning Advances Innovations in Dentistry

Whether creating new teeth, appliances, products, and devices, or studying dental issues of a given population, modern oral healthcare practitioners and product developers are availing themselves of the advanced technology of 3D laser scanning to help them provide the best possible care for as many people as possible. Keeping a smile on people’s faces is much more than just another way of saying “have a good day.” It is a matter of maintaining an innovative up-to-date dental practice and good health.