3D laser scanning offers tremendous time savings and cost benefits for the metal fabricating and sheet metal forming industry. Most importantly, it provides the ability to reverse engineer and inspect complex parts, assemblies and tooling to a higher level of accuracy and in a shorter period of time than with other methods. Instead of collecting points one by one like a coordinate measuring machine (CMM) does, the laser scanner captures tens of thousands of points per second by sensing thereflection of a laser line bounced off the surface of the object. With laser scanning, nearly all die components, regardless of their complexity, can be scanned in minutes to an accuracy of 0.0005 inches, enabling stamping companies to quickly inspect the die or production parts that generate additional revenues by getting dies into production faster.

Laser scanning technology

Laser scanning systems work by projecting a line of laser light onto surfaces while cameras continuously triangulate the changing distance and profile of the laser line as it sweeps along, enabling the object to be accurately replicated. The laser probe’s PC based controller translates the video image of the line into 3D coordinates,providing real-time data renderings that give the operator immediate feedback on areas that might have been missed. Instead of collecting points one by one, the laser scanner picks up tens of thousands of points every second. This allows reverseengineering of the most complicated parts or tooling to be accomplished in ¼ of the time required using conventional touch probe digitizing of the part or tool. Laser scanners are able to quickly measure large parts while generating millions of data points instead of hundreds without the need for templates or fixtures.

Class II diode lasers are used in laser scanners because they do not present a hazard to the human eye. The lasers are about the same power as the bar code scanners used to check out purchases in super markets. They typically have a wavelength of 670 nm which is within the visible spectrum so the eye will blink when exposed to the laser, thus limiting the eye’s exposure to the laser light. The newest generation of probes captures up to 50,000 points per second and weighs less than a pound. The most recent development in laser scanning is the availability of probes with dual detectors that view the laser line from two different directions, reducing the number of scanning passes required to capture steep sidewalls and deep geometries. This new laser probe design further reduces scans times by 30% to 40%.

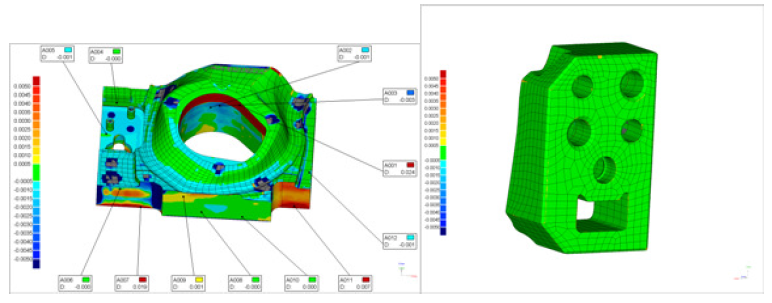

The software provided with the scanner greatly simplifies the process of moving from point cloud to computer aided design (CAD) model, making it possible in minimal time to generate a CAD model of the scanned part that faithfully duplicates the original part. Off the shelf software can be used to compare original design geometry to the actual physical part, generating an overall graduated 3D color error plot that shows in a glance where and by how much, surfaces deviate from the original design. This makes it possible to easily compare the as-built die to the original part geometry to see what changes were made during the debugging or try out process.

Comparison to CMM

The conventional method for digitizing parts and dies is done by using CMMs to capture their geometry point by point. But it has become increasingly difficult to utilize CMMs for this purpose as the complexity of dies tends to increase with each new product generation. The operator must guide theprobe to each individual point. Millions of points are frequently required to fully characterize complex stamping dies. There is never enough time to capture them by hand. This is means that aconsiderable amount of time is required to program the CMM to check out the part or die either off line or at the machine. Reverse engineering the changes made to tooling can take days and is thus rarely done due to this overwhelming time input. When a new tool is needed with the same changes incorporated, the entire process of try out and tooling modification then is reacted. Laser scanning can overcome this problem by capturing the millions of coordinate points so that the CAD modeling changes can be quickly incorporated into the original CAD model for use for repair orreplication.

On the other hand, the CMM provides greater accuracy in determining the position of individual tooling points to an accuracy of 5 microns when needed so it is sometimes used to verify tight tolerance features when a hole center location needs this high accuracy input. Laser scanning heads are commonly mounted on CMM arms so that the CMM’s motion system moves the probe while the probe’s computer monitors the CMM’s encoders to track the probe’s position. The retrofitted CMM can easily be switched between laser scanning and mechanical touch probe measuring modes so that surfaces can be scanned by the laser and points can be digitized with the full accuracy of the CMM device.

Applications in the automotive metal forming industry

Some shifts in the metal forming industry have increased the demand for laser scanning. Many of the stamping dies used by Japanese automobile manufacturers to produce body and chassis components in their United States plants are now built in Asia under very tight deadlines. The dies are generally modified during the proving out process but as soon as they are capable of building acceptable parts it is usually necessary to rush them onto a boat for the trip to the United States. So there often is not enough time to produce the dimensional data that is needed later to produce replacement parts when the die becomes worn or is damaged.

In the past, before they began production, the stamping companies that used the dies sent them out to engineering firms or tool and die shops for reverse engineering with a CMM. This was expensive and time-consuming because of the need to manually move the machine probe around the die in order to capture each of the thousands of points needed to accurately characterize its geometry.

Several innovative companies have improved on the traditional approach by using a laser probe to scan the die surface while viewing the reflected light with a camera that captures millions of points in minutes. “The new high definition laser scanningsystems available today in conjunction with high-end data processing software have given the metal stamping industry the resources to provide very quick and accurate reverse engineering data for the manufacturing of complex surfaced die components,” said the owner of one such company.

“The ability to accurately digitize the existing component to within 12 microns(0.0005 inches) and then, if necessary, virtually recondition the component using the tools within the data processing software has dramatically improved this process,” headded. “The higher scanning speed provided by the new method is another important advantage. An average-sized die component can typically be scanned on all surfaces in about 30 minutes and a large component generally takes less than an hour. This compares to several hours or days that are typically required to digitize similar parts on a CMM.”

Another important application is reverse engineering and inspection of complex sheet metal assemblies. The sheet metal housing shown here was scanned to obtain millions of coordinate points which generated a CAD/CAM model that was used to update the manufacturer’s database of components that have changed since the original CAD models were developed. A color error map was generated to identify exactly how the current product differs from the original design intent. New products can now be developed from existing products by modifying the CAD model level rather than starting from scratch. CAD modeling from laser scan data is typically about eight times faster than the time required for the previous process which involved manually creating the model from CMM touch probe data. The millions of coordinates from 3D laser scanning define all of the subtle freeform and surface transitional shape changes that were difficult or impractical from a time standpoint to measure with touch probe based CMM technology. The advantages of laser scanning in these applications helps explain why the use of this technology is growing so rapidly in the metal forming and fabricating industry.